Capping

Capping of Bottles, Flacons, Cans, Glass, Canisters i.e. with screw caps as well as Press-in-closures, Pump-inserts or Drop-dispensing ....

Content

Capping robot COBRA I

Capping robot COBRA I

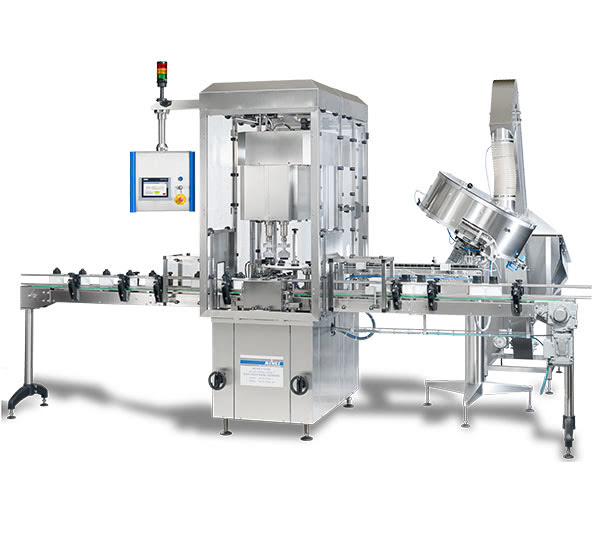

Single-Spindle Capping Machines

Type GKV/GKV-Kombi Servo Control

- Stepless adjustable operating speed

- Opto-electronic congestion-control

- Problem-free format change by using standard component parts

- Fully integrated electrical installation

- PLC Siemens S7 (open program configuration)

- Simple operator guidance through Siemens Touch Screen

- Servo controlled clocked star

- Capping Spindle drive through maintenance-free servo motors

- Electrical controlled stepless torque tightening and capping speed centrally adjustable

- Exact torque speed repetition

- Enormous reserves at high torque tightening speed

- Right/Left capping function

Capping Robot CBM

CBM

- Enormous flexible working range for a wide variety of containers and closure sizes

- Minimum set-up time

- Ideally suited for frequent format change

- Excellent handling, even of large Containers – Non-stop closing of filled containers

- Servo-closing drive with freely programmable torque-speed, rotation-speed, thread pitch and positioning

- Torque-speed control through servo technology with error evaluation

- All format parameters are saved and are reproducible at all times

- Siemens S7 via Siemens Touch Screen

- Integrated separation station without stop-and-go

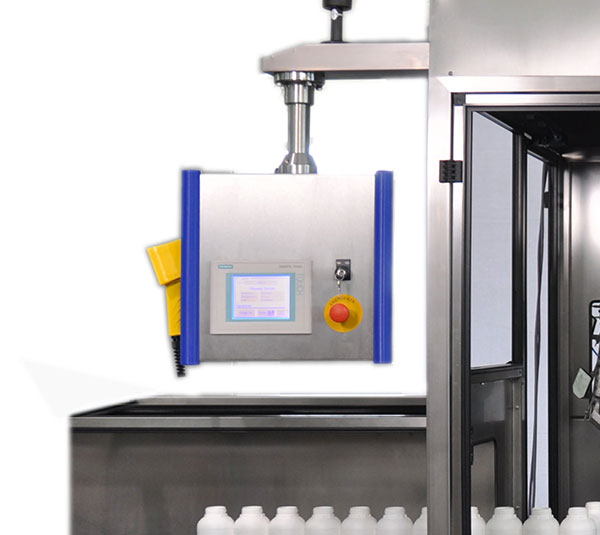

NEW Capping Robot COBRA I

COBRA I

- Ideally suited for frequent format change

- For capping of screw caps as well as press in closures

- Also suitable for pre-positioned closures

- Torque and rotation speed as well as rotation angle parametrization of both capping Spindles through servo drives

- Z-axis-movement of both Spindles through servo drive

- Opto-electronic congestion-control

- Fully integrated electrical installation

- PLC Siemens S7 (open program configuration)

- Closes the gap between 1-digit clocked and continuous rotating capping machines

- Free programming of the Z and Y axis, save as format set

- Tool-free format change

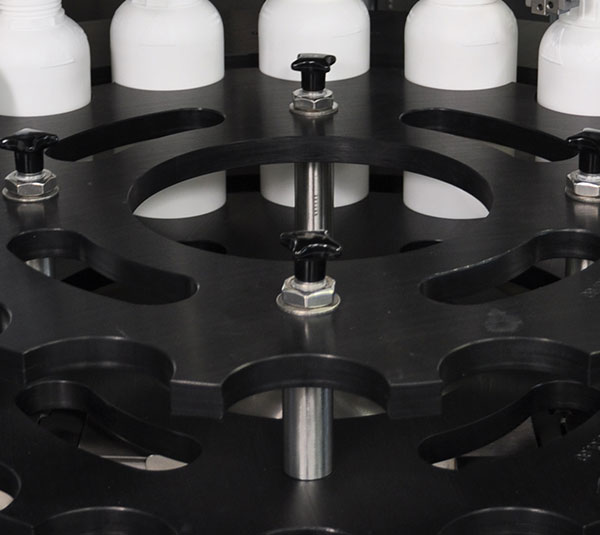

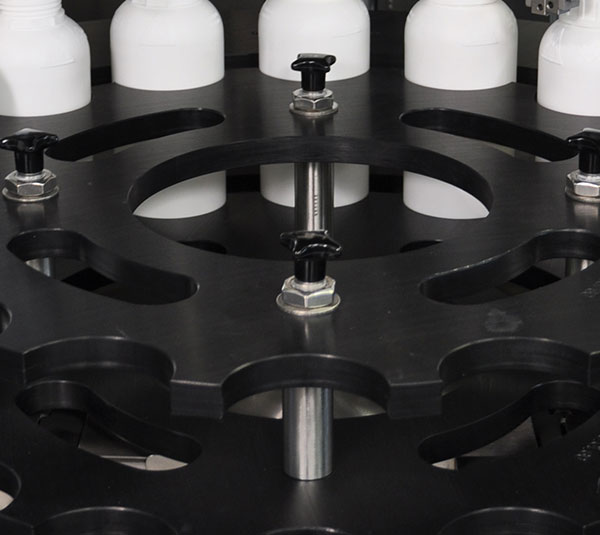

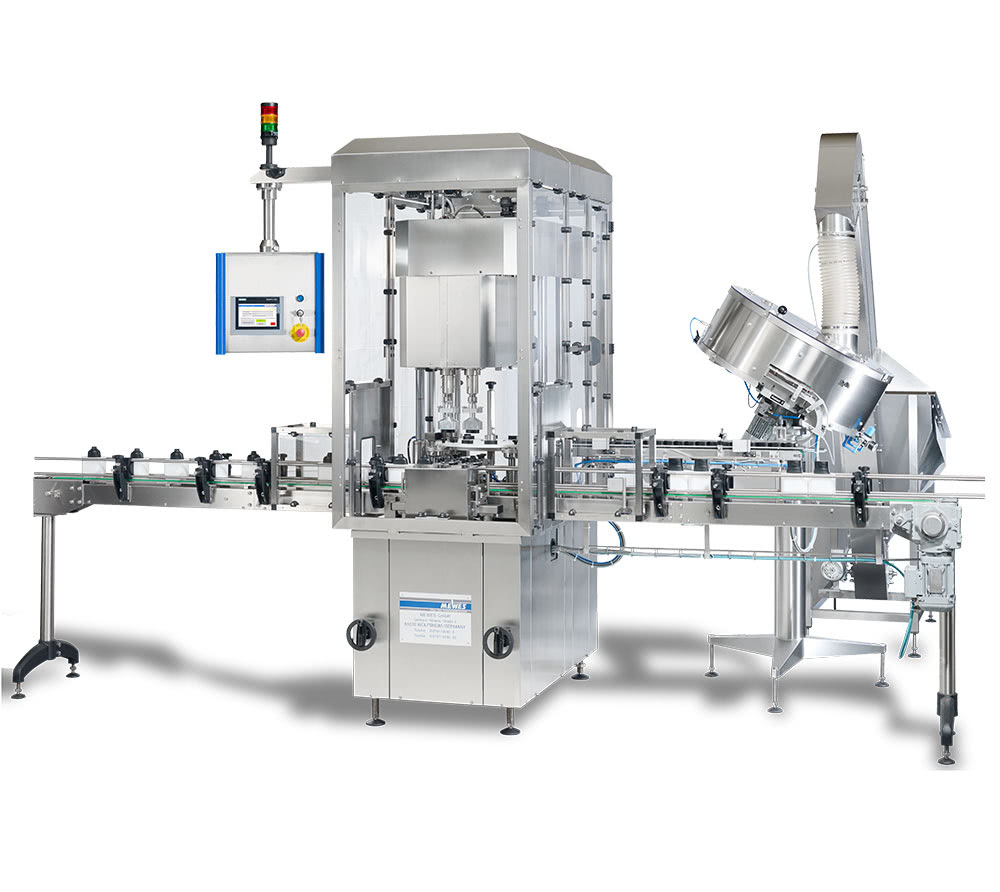

Rotary Capping Machine

Type RLV Servo Control

- Multi-Spindle Capping machine with 4, 6, 8 or 12 Capping Spindles

- Frequency-controlled maintenance-free three-phase motors for stepless- adjustable working speed

- Tightening torque-speed for each Spindle with individual stepless adjustability

- Opto-electronic congestion-control

- Problem-free format change by using standard component parts

- Fully integrated electrical installation

- PLC Siemens S7 (open program configuration) via Siemens Touch Screen

- Capping Spindle drives are driven by maintenance-free servo drives

- Electrically controlled stepless torque tightening and capping speed, centrally adjustable for all Spindles

- Exact repetitive accuracy of the torque tightening settings

- Vast reserves at high torque tightening

- Accurate capping and positioning of each Spindle

- Integrated torque-control

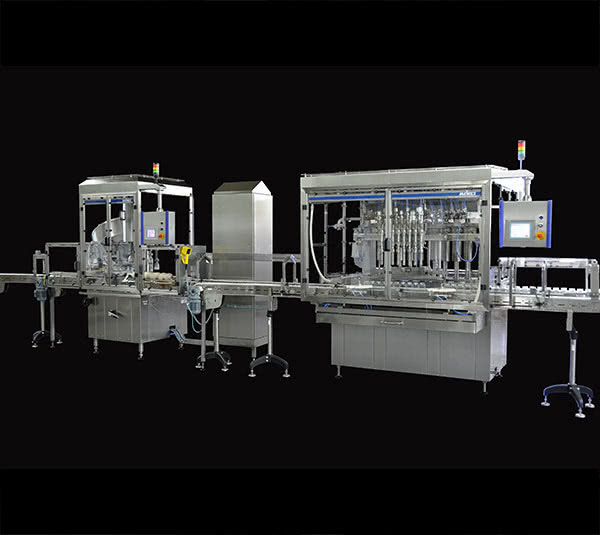

Filling and Capping Machine

Type RTM

Multifunctional in limited space and utmost flexibility through consistent CNC technology

Application:

- Small batch sizes

- Multiple-parts Closure Systems

- The modular construction of the RTM allows for the application of different Dosing and Closure Systems

- CNC-controlled Rotary-clocked Filling and Capping machines

- Optional filling through 1- or 2-digit Piston-Dosing with servo drive, Rotary Piston-Dosing with separate servo drives, mass-flow measuring or weighing elements

- Capping option with either, 1 or 2 digit capping stations with mechanical torque speed limitation or with servo driven torque speed limitation and positioning capability

Equipment

Optional

- Various mechanical / optoelectronic closure controls

- Insertion and press-in devices

- N2-Nitrogen

- Closure Sorter Machines

- Elevator feeders

- Collective Turntable

- Container and closure system VC

- Special equipments

Special design

- ATEX

- GMP / Pharma-line

- Bags

- Pumps

Our depth of manufacture

- Construction

- Conventional + CNC machining

- Complete engineering

- Welding in different classifications

- Switch cabinet construction, PLC programming